Ventilation Systems

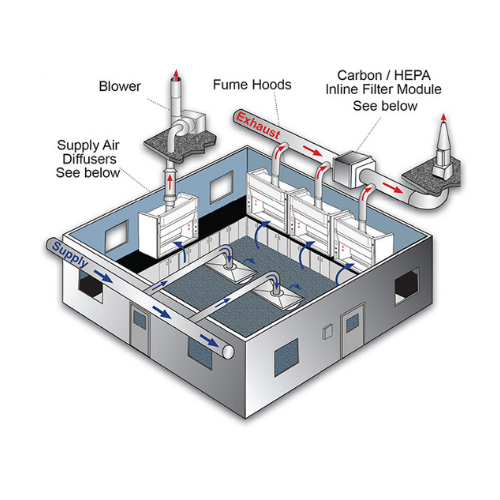

Proper placement and use of fume hoods and blowers are important laboratory ventilation requirements. HEMCO offers the following suggestions to help in your laboratory layout.

- Room air supply, air flow patterns and user convenience are the most important considerations in planning the location of hoods within the laboratory.

- Hoods placed directly in front of doors, open windows, or air conditioning registers will not perform efficiently. Drafts create turbulence at the face of the fume hood and disrupts air flow.

- Hoods should not be placed where users would be forced to work in the line of traffic. Traffic in front of the hood adversely affects fume hood air flow.

- When common exhaust or supply systems are used for several hoods, the hood units should be arranged so minimum amount of ductwork is required.

- Hoods used as general lab exhaust should generally be located on the opposite wall from the side-wall inlet registers or doors. The hoods should be located so that air from the registers or diffusers sweep through the laboratory area first then into the hoods.

Hood Operation

- Consult Lab Safety Officer for correct use of fume hood.

- Hoods should not be used as laboratory storage space. Unnecessary material or unused bottles and flasks can block exhaust openings and interfere with hood performance.

- OSHA requires an fume hood be equipped with an Air Flow Monitor to track air flow velocities and warn operator of potentially dangerous low air flows due to damper, blower failure, blockage of ductwork system, or extreme sash opening height.

Centrifugal Fans

Features

- Installed quickly and easily on reinforced roof curb

- Designed to withstand up to 125 mph wind loads with out guy wires

- Performance capacities range from 270 - 2400 cfm and up to 3.5 in. wg per fan

- Meets ANSI Z9.5 , NFPA 45 and ASHRAE guidelines

- U.L. listed for electrical 705 power ventilators

- AMCA Certified for Sound and Air performance AMCA 210 & 300

- Components are electrostaticaly powder coated with a 2 part corrosion resistant coating, standard color: Gray

- Housing Style is an In-Line Configuration

- 1 Year Warranty

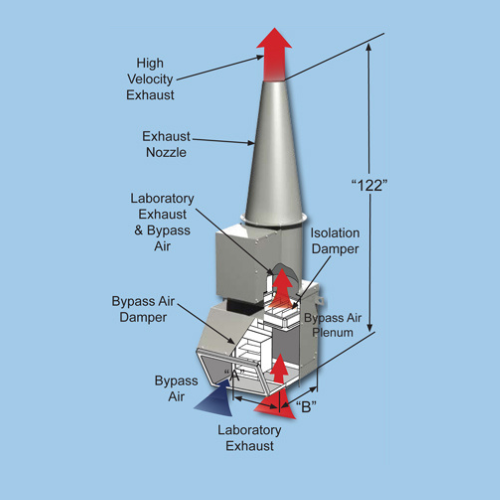

| Unit Size | Cat. No. | Dimensions (Inches) | Performance Range (cfm) | Nozzle Size Range | |||

|---|---|---|---|---|---|---|---|

| A | B | Min | Max | Min | Max | ||

| 9 | 85009 | 21 5/8 | 21 5/8 | 270 | 1750 | 4 | 9 |

| 10 | 8501 | 21 5/8 | 21 5/8 | 450 | 1800 | 5 | 10 |

| 12 | 85012 | 21 5/8 | 21 5/8 | 600 | 2640 | 6 | 13 |

| 13 | 85013 | 23 5/8 | 23 5/8 | 810 | 3160 | 7 | 14 |

| 16 | 85016 | 27 5/8 | 27 5/8 | -- | 7080 | 8 | 18 |

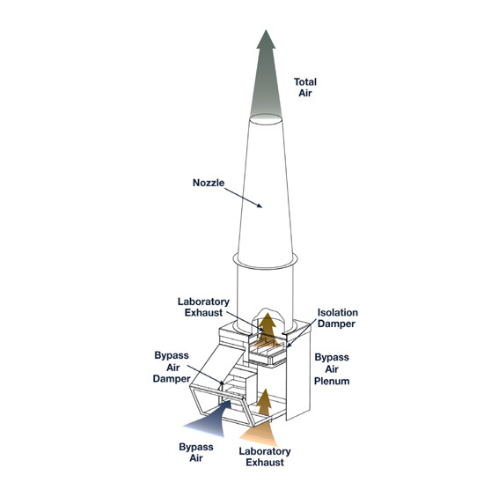

- Housing Style: in-line Configuration

- Stack Style: High Plume Nozzle

- Minimum Flow: 270 cfm

- Maximum Flow: 24,000 cfm

- Maximum ESP: Up to 3.5 in wg (875 Pa)

- UL Listed: U.L. for electrical 705 power ventilators

- AMCA Certified: Sound and Air performance AMCA210 & 300

- Warranty: 1 year